You’ve reached your limit!

To continue enjoying Utility Week Innovate, brought to you in association with Utility Week Live or gain unlimited Utility Week site access choose the option that applies to you below:

Register to access Utility Week Innovate

- Get the latest insight on frontline business challenges

- Receive specialist sector newsletters to keep you informed

- Access our Utility Week Innovate content for free

- Join us in bringing collaborative innovation to life at Utility Week Live

StormHarvester’s AI-backed analysis tools allow water companies to accurately forecast the impact of heavy rainfall events. The automated water management software platform won backing from Wessex Water and has now completed a trial in the Bath area – picking up a Water Industry Award too, as managing director Brian Moloney explains.

Managing sewer blockages represents a significant operational challenge for water and wastewater utilities. As well as problems arising from the blockages themselves, heavy rainfall events often trigger hundreds of alarms, because of rainfall runoff causing high levels within the sewer network. The volume of alarms can be overwhelming for operational and maintenance teams.

Jody Knight, asset technology manager at Wessex Water, explains: “One of the biggest problems we have serving our customers is not knowing where and when blockages will occur, or are likely to occur, in the wastewater network.”

Wessex Water’s goal was to use the latest technologies to gain additional insights from its existing network of wastewater sensors. Specifically, the company wanted to test how well artificial intelligence (AI) could accurately detect early blockage formations, and create smarter control room alarms.

During wet weather, it is difficult to differentiate between expected high sewer levels caused by heavy rainfall volumes, and higher than usual levels arising from restrictions in the network such as partial or total blockages.

If left unchecked, early blockage formations can lead to service failures such as pollution or flooding events. However, if spotted early enough, blockage formations can be cleared and costly service failures avoided. If AI could differentiate between these different events, then it would be possible to achieve an improvement in alarm quality, accuracy and rationalisation.

Challenging times

In spring 2020, Wessex Water ran a challenge project with 16 entrants to demonstrate the value of applying AI, specifically, machine-learning, to its wastewater network.

The solution needed to: be able predict early blockage formations before they become service failures; work alongside its condition-based maintenance programme; and differentiate between genuine control room alarms from those triggered simply because of high volumes of rainfall.

StormHarvester became a finalist and implemented a three-month proof of concept. In designing the trial, Wessex Water set the following parameters.

First, the system had to produce results in real-time; be sensor agnostic; and work across both sewer pipes and pumping stations.

It also had to be able collate sewer depth information and compare this to time-series data, as well as upstream rainfall intensity data. Then – for each sewer asset – it had to be able to produce an accurate, predicted operating depth band for the prevalent conditions.

Wessex Water also wanted to see its level of false positive alerts drop significantly. The solution had to be cloud-based, and cost the utility company £10,000 or less.

Bath-time for software solution

In summer 2020, StormHarvester deployed its Intelligent Sewer Suite product to provide real-time predictions and alerts on early blockage formations in the sewer network for the city of Bath. The alerts identified potential noncompliant out-of-sewer pollution events before they occurred so that maintenance crews could proactively remedy issues before they resulted in service failures, such as pollution or flooding.

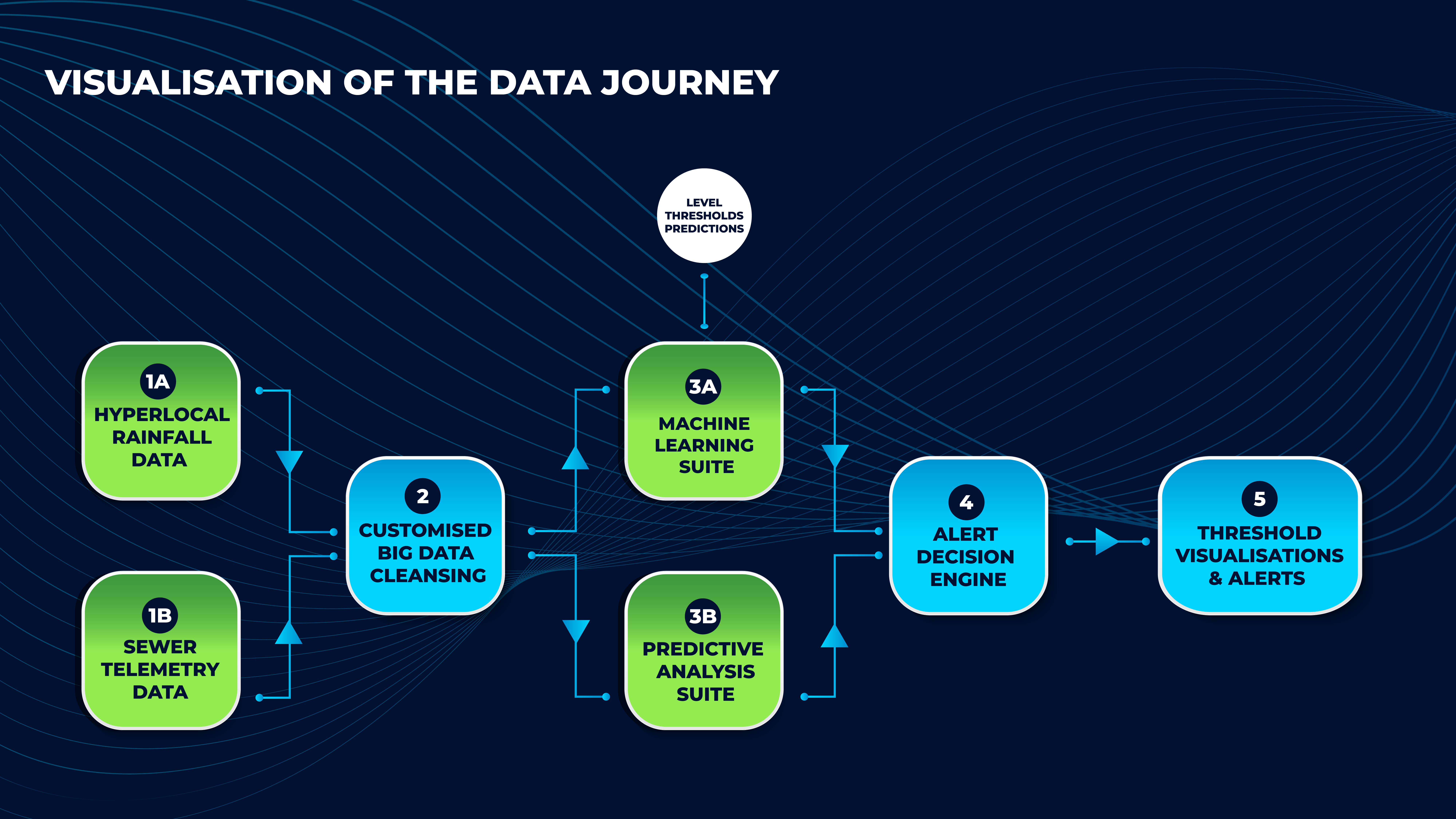

The Intelligent Sewer Suite’s proprietary machine learning, AI algorithms and predictive analysis tools were used on both combined sewer overflow (CSO) and pumping station sensor data, with corresponding hyperlocal rainfall forecast data, to predict network levels and detect potential blockage formations in real-time.

Only existing sensors were used for this purpose and no new sensor installations were required.

The StormHarvester system took only three weeks to set up before it developed usable results. The process involved extracting historic sewer level data and historic rainfall levels in a 1.5km square grid for each of the 98 assets; the system then undertook tens of millions of iterative calculations to ‘learn’ sewer asset behaviour in both dry and wet weather periods.

The safe operating window, or thresholds, were predicted using several factors, including time of day, the day of the week, hyperlocal rainfall and local river and borehole levels. These dynamic thresholds are predicted for six hours into the future and updated every 15 minutes on an asset level. The StormHarvester software solution did not require or utilise any hydraulic models, which was key to its quick set up and accuracy.

Edmund Willatts, asset reliability engineer at Wessex Water, has benefitted from its insights. “The StormHarvester system used machine learning to set safe operating windows or thresholds for each asset. Each time these had a significant breach, we received alerts, which in turn were passed to the Operations team so that they could respond.”

The Environment Agency, while pressing for zero pollution incidents for the water industry in England, currently puts incidents into four categories. Category 4 is the least serious and has no impact on company performance, while Category 3 incidents can impact on performance commitments and risk breaches of environmental protection and water industry legislation. They can also lead to significant costs, including emergency response charges and penalties from regulators.

In three months, StormHarvester’s Intelligent Sewer Suite detected over 60 early blockage formations in real time, at least two of which were likely to have caused significant pollution incidents – in the more serious Category 1, 2 or 3 – if it had not been for these alerts.

Over 60 telemetry and sensor faults were also detected in real time. Wessex Water considered the alerts provided by StormHarvester a major improvement on the status quo where operational staff were regularly overwhelmed by the large number of high-level and overflow alarms occurring in the control room during periods of heavy rainfall.

Based on the value brought by the StormHarvester alerts, Wessex Water decided to keep the alerting system running on the Bath catchment after the initial trial.

Knight says: “During the trial, StormHarvester were able to identify sewer blockages very early on and we were therefore able to get the operation teams to proactively intervene. This significantly increased our chances of making it quicker and easier to spot spillages.”

The Wessex pilot was able to achieve high accuracy in blockage prediction and early blockage alert accuracy: 92 per cent of the alerts StormHarvester provided were relevant and required, and the trail saw fewer than 10 per cent false positives. Most importantly, not a single blockage resulting in a pollution incident was missed.

Early blockage formations were identified up to eight weeks before they would have resulted in service failures, and the three-month trial has enabled a major shift towards a condition-based maintenance approach.

In the Wessex Water control room, 4,500 alarms were generated during the pilot period. However, it was calculated that utilising the StormHarvester solution across the network to replace the incumbent rules-based alarms system, a 97 per cent reduction in control room alerts would have been achieved. StormHarvester alerted only 138 times, which is considered a manageable volume, meaning Wessex Water’s operational and maintenance crews could respond to these ‘smart alarms’ even during periods of heavy rainfall.

Brian Moloney was working as a civil engineer in Queensland, Australia in 2012 when he realised that if rainwater harvesting tanks were drained en masse ahead of a storm, the additional water storage capacity could significantly abate the regular flooding experienced in the region. This led to three years of R&D with Queen’s University in Belfast, United Kingdom, and the launch of StormHarvester’s automated water management software platform in 2016. Backed by venture capitalists, the business has partners in over 20 countries and is now using machine learning to tackle problems in Wastewater Networks such as sewer blockages and Combined Sewer Overflows or escapes.

Please login or Register to leave a comment.