You’ve reached your limit!

To continue enjoying Utility Week Innovate, brought to you in association with Utility Week Live or gain unlimited Utility Week site access choose the option that applies to you below:

Register to access Utility Week Innovate

- Get the latest insight on frontline business challenges

- Receive specialist sector newsletters to keep you informed

- Access our Utility Week Innovate content for free

- Join us in bringing collaborative innovation to life at Utility Week Live

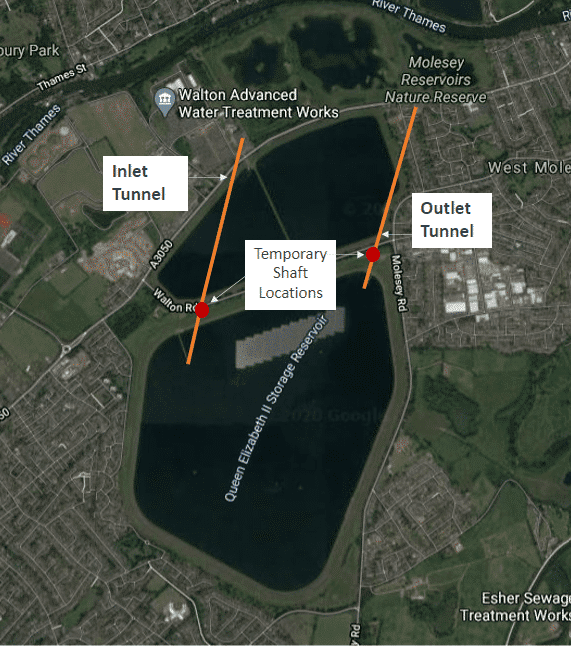

Storing around 10% of the capital’s water, the Queen Elizabeth II (QEII) Reservoir being under maintenance for the best part of 2021 necessitated an urgent shake-up of London’s water. Here, project leaders from Thames Water discuss the process of taking the reservoir out of action and £25 million worth of upgrades.

Found in the Surrey market town of Walton-on-Thames – roughly 15 miles from central London – plans for the QEII Reservoir were first drawn up in 1935 before construction began a year later. While work was suspended during the Second World War, it restarted in 1957 before the reservoir was formally opened by its namesake in March 1962.

Now, just shy of the site’s diamond jubilee, £25 million worth of improvements to ensure a further century of service are drawing to a close.

As per the Reservoirs Act 1975, the assets must be inspected at least every 10 years, with Thames Water – which serves 15 million customers across London and the Thames Valley – using the latest mandated checks as an opportunity to examine, clean and maintain the transfer tunnels that feed water to and from the QEII.

Subsequently, a project to upgrade the 20,000 million litre reservoir – the equivalent of around 8,000 Olympic swimming pools – began in April 2021 and has seen the installation of reinforced concrete linings in both its 1,035m long inlet and 795m long outlet tunnels.

Subsequently, a project to upgrade the 20,000 million litre reservoir – the equivalent of around 8,000 Olympic swimming pools – began in April 2021 and has seen the installation of reinforced concrete linings in both its 1,035m long inlet and 795m long outlet tunnels.

When complete, the scheme will help prevent future leaks, avoid potential supply restrictions and ensure a design life of up to 100 years.

Please login or Register to leave a comment.