You’ve reached your limit!

To continue enjoying Utility Week Innovate, brought to you in association with Utility Week Live or gain unlimited Utility Week site access choose the option that applies to you below:

Register to access Utility Week Innovate

- Get the latest insight on frontline business challenges

- Receive specialist sector newsletters to keep you informed

- Access our Utility Week Innovate content for free

- Join us in bringing collaborative innovation to life at Utility Week Live

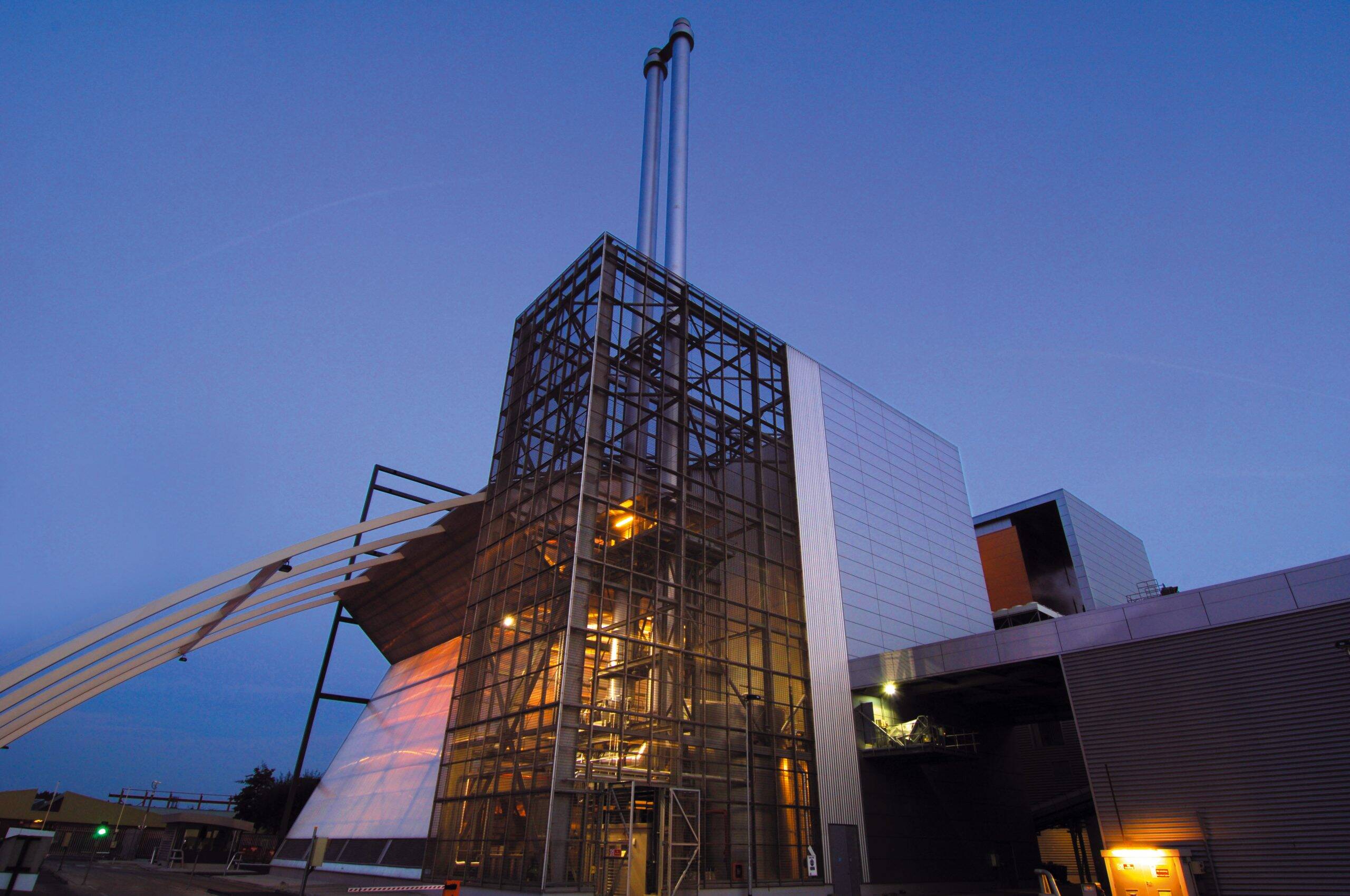

Veolia's chief operating officer — treatment, Donald Macphail, explains how the firm's energy recovery facilities (ERFs) are helping to cut healthcare's post-pandemic carbon footprint.

According to its latest figures, Veolia’s ten ERF plants currently take around 2.3 million tonnes of non-recyclable waste and convert it into electricity for over 400,000 homes.

These facilities are said to generate around 1.4TWh of electricity through non-recyclables per year and have helped tackle pandemic medical waste — such as used test kits and PPE — by treating a 15 per cent increase in orange bagged clinical and infectious materials.

Veolia’s Donald Macphail describes producing secure energy from such items as a “win-win situation” — generating greener electricity and heat, reducing landfill, and striving for greater sustainability.

“As more baseload generators such as nuclear, coal and CCGTs retire, ERFs’ are set to play an increasingly important role in keeping the lights on during winter evenings and during days where wind generation is low,” he explains.

“Future development will increase this importance and we are already advancing trials of the latest carbon capture technology, and taking another step towards a zero carbon future.”

How do Veolia’s ERFs work?

During a recent demonstration, Veolia’s ERFs delivered nearly 25 per cent more energy than wind power — at one stage producing 111MWe versus total wind generation of 58MWe.

According to Macphail, once recyclables have been removed, waste delivered to these plants is burnt in what he describes as “carefully controlled conditions”. “The heat from the combustion process is used to turn water into steam,” he says. “The steam then powers turbines to generate electricity for export to the National Grid.

“Hot water is recovered from the generating process and can be used by connected district heating networks. The water used in the process is recycled.”

Macphail adds that ash from the process, known as incinerator bottom ash, contains gravel-like glass, brick, stone, concrete and ceramic remnants, and can be recycled into construction aggregate — replacing quarried material in asphalt and cement production.

“The gases from the boiler are extensively cleaned including neutralising any acid gases, removing pollutants with ‘activated carbon’ and capturing fine particles with a fabric filter,” he continues. “The gas treatment residues are kept in enclosed storage on site and then disposed of safely at a licensed facility.”

Lowering healthcare’s carbon footprint

Expanding on the broader implications of Veolia’s ERF demonstration versus wind power in July, Macphail says that creating more baseload electricity for the UK power network complements existing generation assets.

“ERFs operate 24 hours a day and represent a continuously available and resilient low carbon baseload energy source,” he says. “Wind and solar power are good renewable energy sources but their intermittent availability and varying output means that there is a generating gap.

“Electricity powers the modern world and daily life, from the internet of things to electric vehicles. With the decarbonisation of heat in homes, a resilient electricity supply that has 24 hour consistent availability is essential. The ability to export heat from ERF also means that district heating schemes become more viable.”

Macphail adds that the pandemic has demonstrated that ERF can be adapted to handle new, and pressing, waste streams effectively.

“The safe disposal of Covid related wastes in ERF has shown significant emissions reductions can be achieved by by disposing of the more than 61,000 tonnes of orange bagged clinical and infectious waste that arises each year,” he says.

“By using ERF, this type of clinical waste can be safely and compliantly destroyed, and achieve up to 70 per cent reductions in carbon emissions compared to commonly applied treatments.

“The UK has a legal obligation to meet a Net Zero Carbon position by 2050, which will benefit the UK in terms of environment,” he continues. “As we look to cut carbon, and develop energy resilience, one area where we believe significant emissions reductions can be achieved is in clinical waste treatment, specifically for orange bagged waste.

“As we look to build a green recovery following the pandemic, using ERF technology could help make a real contribution to lowering the carbon footprint of healthcare.”

Future development

Macphail’s “ideal forward vision” is that the network of ERFs can be expanded and linked to district heating networks that can supply communities, commercial and public buildings, and industry.

“Future development will increase the importance of ERFs and we are already advancing trials of the latest carbon capture technology to achieve net zero carbon energy delivery, and taking another step towards a zero carbon future,” he explains.

ERF technology, backed by both the DEFRA Resources and Waste Strategy and the independent Climate Change Committee, is an important source of renewable, sustainable energy and a vital link in the waste management chain, Macphail believes.

“Veolia’s ERFs complement integrated local waste strategies, helping to meet recovery and carbon emission targets,” he explains.

“Waste reduction, recycling and materials recovery operations are the first priority for our integrated contracts. Once we have optimised these operations, it makes sense to recover energy from the remaining waste where possible.”

Addressing misconceptions

Any further innovation regarding Veolia’s ERF is likely to cover carbon capture and storage, continued optimisation that improves efficiency, and more utilisation of the thermal energy in district heating networks.

“To reduce transport and export of refuse derived fuel, more local systems are needed, both to effectively recycle materials and to use the residual waste for energy generation in the area where the waste arises,” Macphail says.

“Energy costs may also play a part,” he adds. “If ERF electricity and heat is supplied directly — via private wire or heating network — at a lower cost per unit than other sources this will make it more attractive to users.”

However, Macphail explains that wider public understanding of the role of ERFs is central to guiding planning decisions for new sites. He describes the notion that plants are simply incinerators and reduce the amount of recycling as a “common misconception”.

“The key point is that recycling materials is a valuable source of revenue so it would not make sense to use these materials for energy recovery,” he says. “Only non recyclables, traditionally destined for landfill, and materials such as Covid medical wastes are used in the ERF process.

“If communities are able to understand the connection between waste, resources, recycling and carbon that will help them to create less waste, and will aid local adoption of ERF.”

See this content brought to life at Utility Week Live, 17-18 May 2022 NEC Birmingham

Delivering smart energy networks is one of the frontline challenges at the heart of Utility Week Live 2022’s live content programme.

View the challenges and be alerted for tickets to the industry’s most eagerly awaited reunion at utilityweeklive.co.uk.

Please login or Register to leave a comment.