You’ve reached your limit!

To continue enjoying Utility Week Innovate, brought to you in association with Utility Week Live or gain unlimited Utility Week site access choose the option that applies to you below:

Register to access Utility Week Innovate

- Get the latest insight on frontline business challenges

- Receive specialist sector newsletters to keep you informed

- Access our Utility Week Innovate content for free

- Join us in bringing collaborative innovation to life at Utility Week Live

In a first weekly round-up of innovation project news, the East Coast Hydrogen Consortium unveils a feasibility report on adapting north east England’s gas network for hydrogen, EDF and Veolia announce a vitrification rollout and Severn Trent captures carbon from sewage treatment.

£863 million hydrogen project in the pipeline for Northeast England

The East Coast Hydrogen Consortium – comprising Northern Gas Networks, Cadent Gas and National Grid – has launched a feasibility report detailing a £863 million pound plan to adapt north east England’s gas network for hydrogen.

The document predicts that hydrogen could be used to supply 4.4 million households and as many as 39,000 industrial and commercial gas users for approximately £13 pounds per household, per year. East Coast Hydrogen also claims to have the potential to connect up to 7GW of hydrogen production by 2030 – exceeding the UK Government’s 5GW by 2030 target.

The report adds that the consortium can achieve this using natural assets – including existing and potential hydrogen storage facilities – and build on hydrogen production in two of the UK’s largest industrial clusters in the north east and north west.

According to East Coast Hydrogen, the project would be the first step in the conversion of the national gas grid to hydrogen and could act as a blueprint for future conversions across the UK while creating tens of thousands of jobs in the future hydrogen economy.

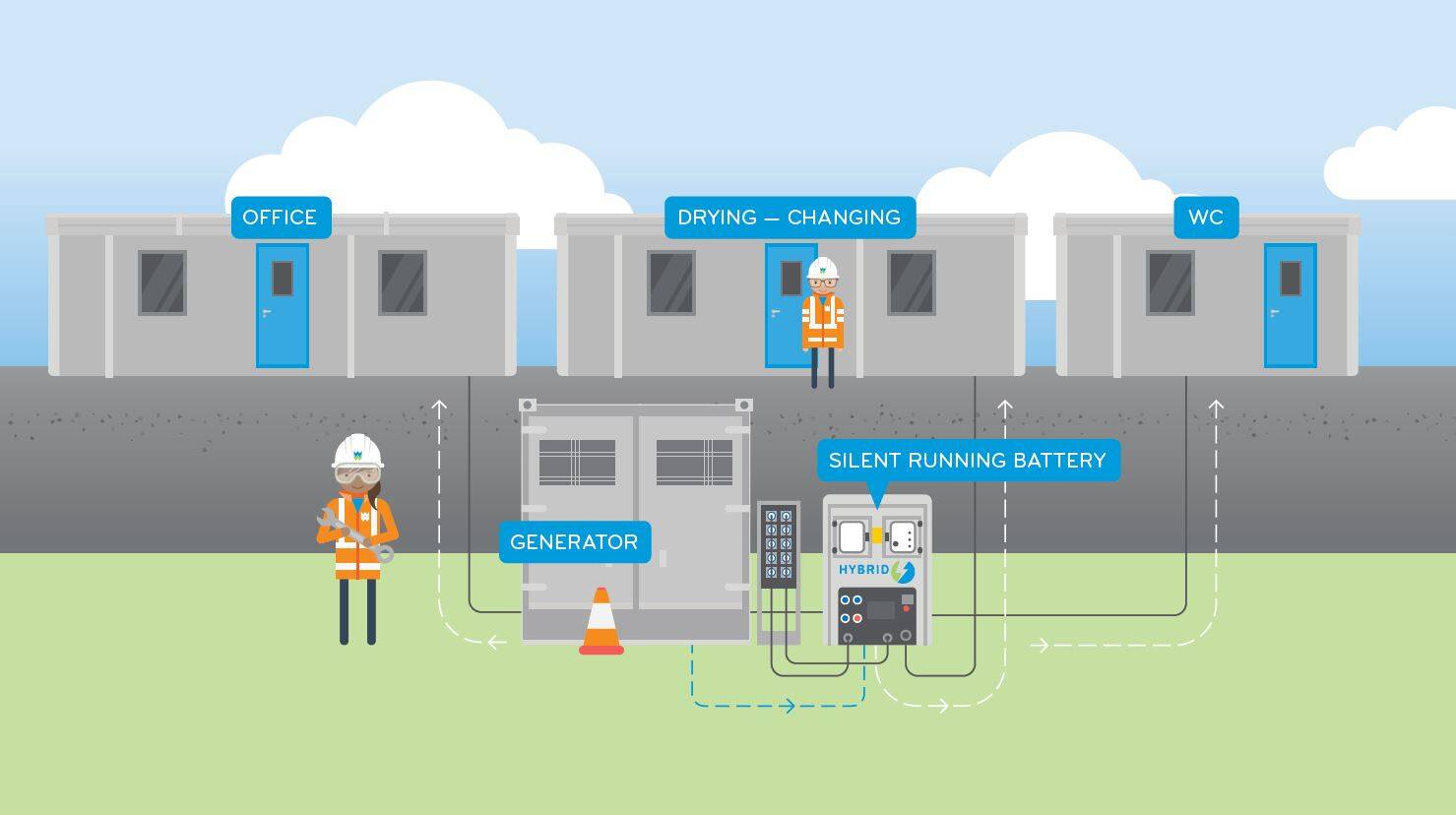

Welsh Water trialing hybrid generator to tackle £10 million project process emissions

Dŵr Cymru Welsh Water is trialing a hybrid generator at one of its sites as part of a £10 million investment in the Rhymney Valley, with the aim of generating an emission free site.

The hybrid generator – which uses hydrotreated vegetable oil and batteries – is currently being used to power the offices, drying rooms and toilets at one of the project’s largest site compounds.

Its use alongside a generator to power the compound has allowed the company to reduce generator size and run time by 55% – meaning that for an average of 12-and-a-half hours each day the site is running off battery power alone.

“The hybrid generator in Rhymney has helped save more than 7,500 litres of fuel over a two-month period, reducing carbon emissions that would normally have been generated from the site by 19 tonnes,” Alexander Herridge, carbon manager at Welsh Water, said.

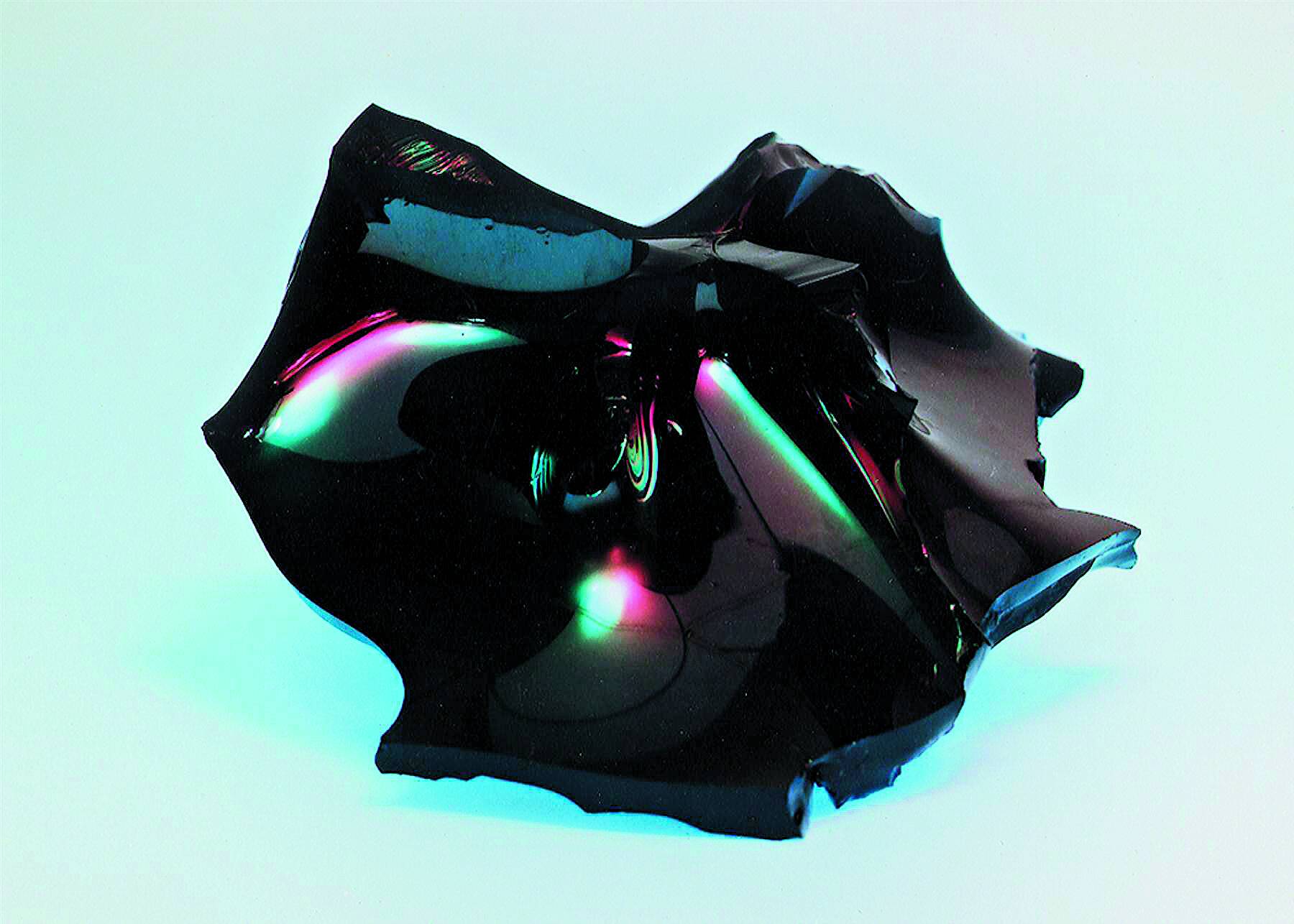

EDF and Veolia announce Waste2Glass

EDF and Veolia have created Waste2Glass – a joint venture deploying Veolia’s Geomelt vitrification technology on an industrial scale and renewing their shared commitment to the treatment of radioactive waste.

Due to its technical nature and cost, vitrification – the transformation of a substance into a glass – has until now been reserved for highly radioactive waste. However Waste2Glass will make it possible to broaden and simplify the process for a wider range of waste types.

Due to its technical nature and cost, vitrification – the transformation of a substance into a glass – has until now been reserved for highly radioactive waste. However Waste2Glass will make it possible to broaden and simplify the process for a wider range of waste types.

“Our business and our purpose as a world leader of the ecological transformation is to offer innovative technologies and solutions for the management of complex waste such as hazardous and radioactive waste,” Antoine Frérot, chairman and CEO of Veolia said.

“I am delighted that we have taken this further step in our collaboration with EDF with the creation of Waste2Glass,” he added. “It will enable a real change of scale through the industrialisation of GeoMelt, which will make it possible to treat radioactive waste more safely and more economically, with a reduction in storage volumes.”

Sustainable cement production facility awarded £500K grant

A facility which will enable the production of lower carbon cement products in partnership with the University of Strathclyde’s Civil & Environmental Engineering Department and Construction Scotland Innovation Centre has secured a £500,000 award from Zero Waste Scotland’s Circular Economy Investment Fund.

The site is being launched by Innovative Ash Solutions (IAS) – a joint venture between resource management company Levenseat and environmental compliance experts Organic Innovative Solutions.

The funds will support the development of an industrial scale facility capable of processing up to 20,000 tonnes of incineration fly, cyclone and boiler ash into a sustainable form of pulverised fuel ash (PFA) – a key ingredient in cement.

The funds will support the development of an industrial scale facility capable of processing up to 20,000 tonnes of incineration fly, cyclone and boiler ash into a sustainable form of pulverised fuel ash (PFA) – a key ingredient in cement.

Using this process – which diverts waste materials from landfill and avoids the use of virgin sand – creates a product which is cheaper and will reduce the environmental impact of concrete production compared to the use of imported PFA.

“Our product not only provides a cheaper concrete option, it also means lower emission concrete production by using a safe, accredited end-of-waste solution made from materials diverted from landfill sites,” IAS’ director Robert Green said. “This provides a win-win scenario for construction companies which are facing rising costs and additional pressures to lower their carbon footprint.”

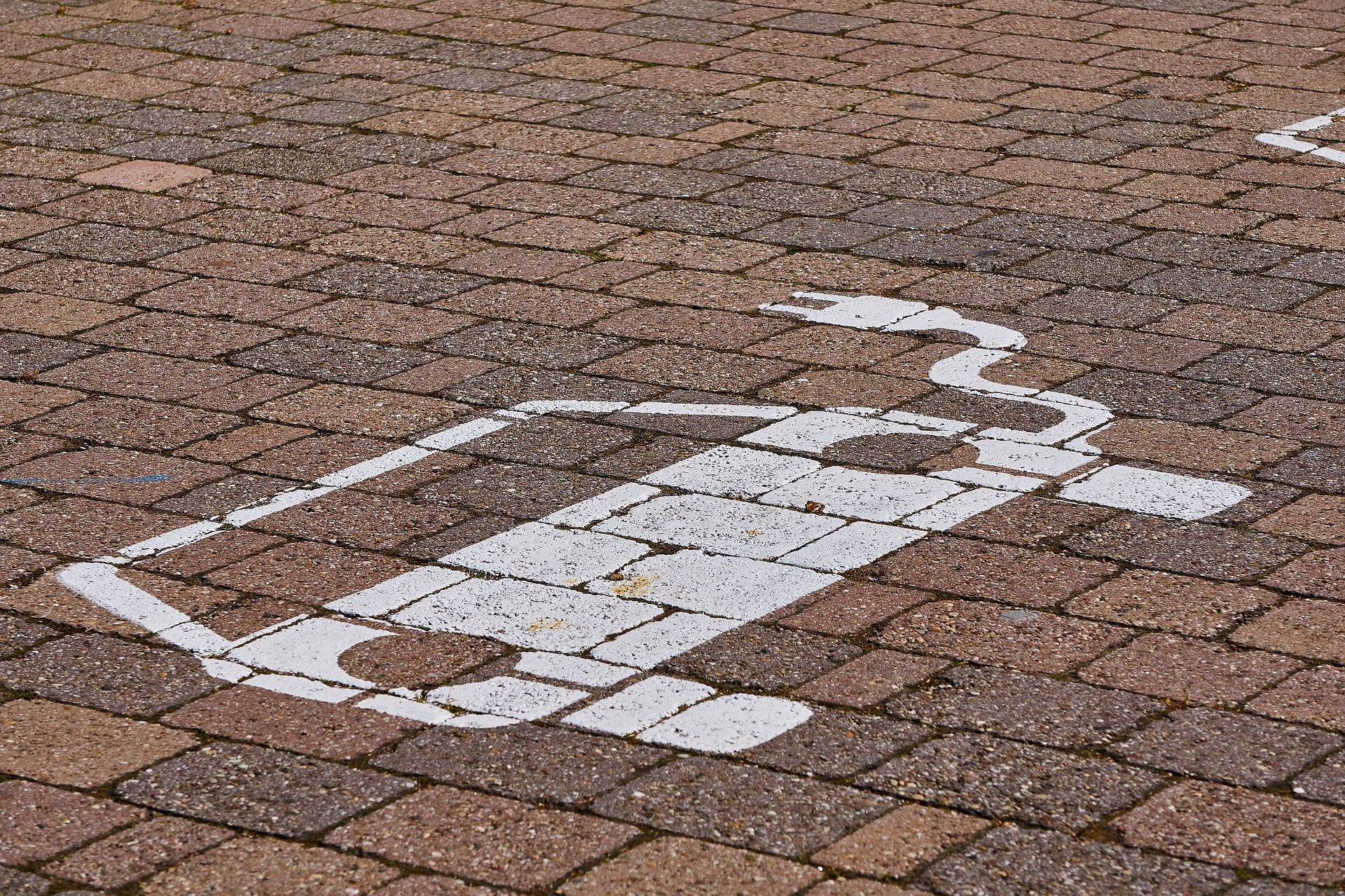

AFP to publish kerbside electric vehicle charging map in early 2022

A map showing street-by-street demand for electric vehicle kerbside charging across the UK is on course to be published by the Association of Fleet Professionals (AFP) in early 2022, the body has announced.

Following the formation of its Kerbside Charging Group in October, the AFP is aiming to collate postcode data gathered from organisations including Royal Mail, Centrica, OpenReach, DEFRA, Mitie, Capita, National Grid and SSE on around 160,000 potential and existing drivers.

Following the formation of its Kerbside Charging Group in October, the AFP is aiming to collate postcode data gathered from organisations including Royal Mail, Centrica, OpenReach, DEFRA, Mitie, Capita, National Grid and SSE on around 160,000 potential and existing drivers.

The map can then be used by national and local government – as well as charging and electricity suppliers – to gauge where kerbside chargers are most urgently needed.

“Every day we are hearing from fleets, especially van fleets, that want to speed up the electrification of their operations but are being hampered by the problem of charging for drivers who do not have a drive or any other access to a charger,” AFP chair Paul Hollick said.

“This is generally thought to be about 40% of drivers across all fleets but, when it comes to light commercial vehicles, we believe the figure to be nearer 70%. That means good availability of kerbside charging is essential if van electrification is going to be a success.”

“Our plan is to be able to create a map early in the New Year that will show on a street-by-street basis where kerbside charging is required,” he added. “This will be a crucial tool when it comes to making fleet electrification happen faster.”

Thames Water launches ‘Business Water Use Calculator’

A free online tool to help UK businesses save water and improve their sustainability approach, the ‘Business Water Use Calculator’ – which Thames Water claims is the first of its kind for non-household water customers – has been launched to cater for the leisure, retail, hotel and hospitality sectors as well as offices.

The calculator asks users to provide information about the sector they represent, how many employees they have and how water is used on the premises – including how many toilets, sinks and showers there are and how often the building is occupied.

At the end of the process they receive a tailored report including a breakdown of their water use along with details of potential water savings and energy and carbon savings from using less hot water.

Veolia to step up use of ERFs in hydrogen production

Veolia has announced plans to accelerate its use of low carbon electricity from energy recovery facilities to power the electrolyser technology it uses to derive hydrogen from water.

As previously reported by Utility Week Innovate, these facilities are said to generate around 1.4TWh of electricity through non-recyclables per year and have helped tackle pandemic medical waste — such as used test kits and PPE — by treating a 15 per cent increase in orange bagged clinical and infectious materials.

As previously reported by Utility Week Innovate, these facilities are said to generate around 1.4TWh of electricity through non-recyclables per year and have helped tackle pandemic medical waste — such as used test kits and PPE — by treating a 15 per cent increase in orange bagged clinical and infectious materials.

It’s believed that their use in hydrogen production is the first application of its type in the UK.

Commenting on this latest zero carbon initiative, Donald Macphail, chief operating officer, treatment, at Veolia said: “By developing new ways of generating zero carbon hydrogen we have the potential of covering the energy needs of our modern lives, and stopping the climate damaging impact of CO2. This represents a real step forward on the route to a net-zero world.”

Bill and Melinda Gates Foundation funding off-grid toilet

The Bill and Melinda Gates Foundation is funding efforts by Aqua Enviro – a Suez Group specialist environmental consultancy – and Cranfield University to develop a non-sewered, self-contained, ultra-low water system designed to convert human waste to clean water and ash.

The Circular Processing Toilet is intended to enable communities without access to centralised sewerage infrastructure to have a hygienic means of treating waste without polluting nearby water resources or using harmful chemicals.

The Circular Processing Toilet is intended to enable communities without access to centralised sewerage infrastructure to have a hygienic means of treating waste without polluting nearby water resources or using harmful chemicals.

Aqua Enviro has been providing analytical services to evaluate the performance of the system, specifically regarding microbial contamination and final effluent quality.

“We were contacted by Cranfield University to carry out this work because of our knowledge of wastewater treatment processes and our ability to provide rapid turnaround on analysis results,” Paul Pickard of Aqua Enviro commented. “The testing requirements in the ISO standard were interpreted to ensure the appropriate analysis was performed and meaningful results were issued, allowing the team at Cranfield to make regular adjustments to their system.”

Severn Trent captures carbon from sewage treatment

As reported by Utility Week, Severn Trent has utilised carbon capture technology in sewage treatment processes to create a sustainable fertiliser from waste.

The company partnered with CCm Technologies to use captured carbon dioxide to stabilise nitrogen, phosphates and organic chemicals contained in waste and turn it into plant nutrients.

The project at Severn Trent’s plant near Birmingham represents the first time the technology has been applied to the wastewater treatment process.

Rich Walwyn, head of asset intelligence and innovation at Severn Trent, said the first batch of the “super fertiliser” is ready from the project, which is partly funded by the Department for Business, Energy and Industrial Strategy’s (BEIS) Industrial Energy Efficiency Accelerator (IEEA) programme.

Rich Walwyn, head of asset intelligence and innovation at Severn Trent, said the first batch of the “super fertiliser” is ready from the project, which is partly funded by the Department for Business, Energy and Industrial Strategy’s (BEIS) Industrial Energy Efficiency Accelerator (IEEA) programme.

“Using carbon capture technology, we’re able to treat waste in a much greener and more efficient way than ever before, as well as getting a fantastic product at the end, which has carbon locked into it,” he said. “This new approach has taken us a step closer to making sure absolutely nothing is wasted, in the sewage treatment process.”

Continue reading here

See this content brought to life at Utility Week Live, 17-18 May 2022 NEC Birmingham

View the challenges and be alerted for tickets to the industry’s most eagerly awaited reunion at utilityweeklive.co.uk

Please login or Register to leave a comment.